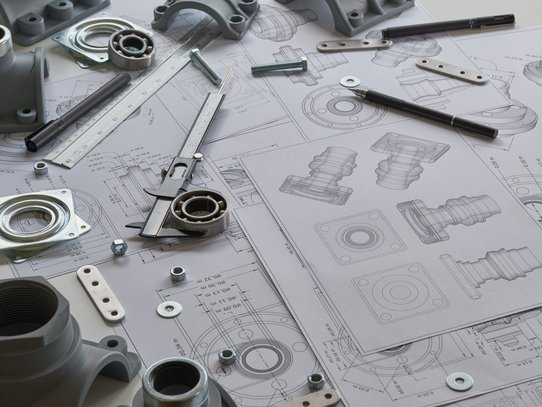

ENGINEERING

Based on 50 years of project experience in the field of individual stamped parts, formed parts and deep-drawn parts, we have developed the "Meese Project Master" in order to provide our customers with optimum and customised support throughout the various phases of an engineering project. The later errors are discovered in the course of the project towards series production, the more expensive it becomes. We therefore look for optimisation potential as early as the first customer sketch.

The Meese Project Master includes the following steps.

Product definition:

- The first step of the producibility analysis / manufacturability analysis and the manufacturability assessment is an examination of the customer's requirement (CAD design data, drawing, specifications, standards and specifications).

- The aim here is to check whether the product is sufficiently defined to enable a manufacturability analysis. If a CAD drawing is available, the redlining function can be used to exchange additional information and comments within the CAD drawing.

- In this project phase, initial ideas for queries can already arise, especially in connection with the planned application.

- A member of our team becomes your permanent contact person.

Check manufacturability, tooling, process:

- Once all the information for the product definition is available, various component features are checked in order to develop a quotation proposal together with you.

- For project management, for example, the following are investigated: materials, design & geometry complexity class, radii, surfaces, quality characteristics, process view and material handling, planned defect rate, usefulness of prototypes, simulation or enlarged 3D printed models, assembly & subassemblies, packaging etc.

- Once the component characteristics are available, the specialists from our toolmaking department are called in to develop the tool design and calculate the tool production.

- During this phase opportunities again arise to identify weak points in the design, calculation and construction together with our customers in order to achieve a cost reduction and/or quality improvement.

Taking the idea into series production

- Despite all the planning, there is a possibility that optimisation potential will be discovered during the start-up phase and later the series production phase.

- This situation is also taken into account in the Meese Project Master. Quickly implementable on-line conferences with all specialists and corresponding image material provide a rapid remedy.